Ring Joint Gasket

Ring Joint Gasket

CHARACTERISTIC This ring joint gasket designed for use in high pressure, temperature applications necessitated the need for a high integrity should always be less than the hardness of the flanges. seal. They are mainly used in the high pressure vessel, pipe flanges, valve bonnets handling high pressure steam, gas, hot oil, oil gas, solvent vapor industries, etc. A wide range of sizes and materials are available on request. The hardness of the ring

-

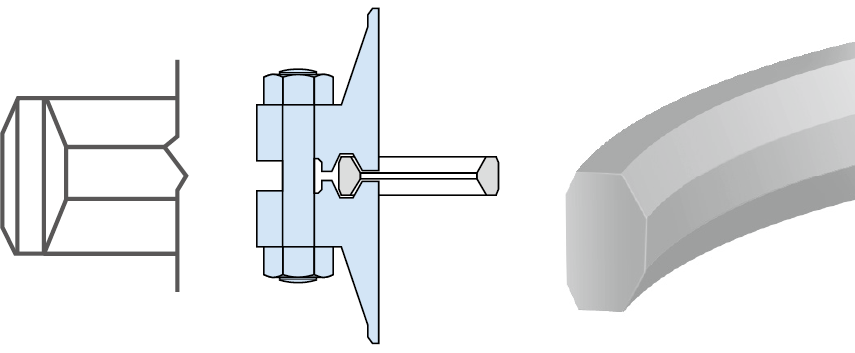

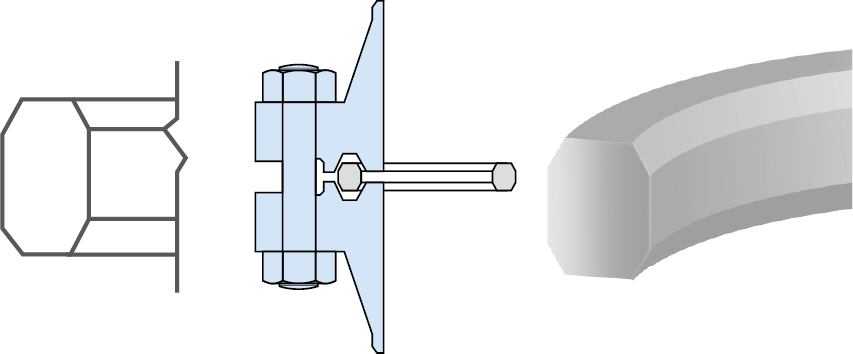

Ring joint Oval Type

This type is the original Joint design. Contacts flange face at the curved surface and provides a high reliability seal. But due to its shape, it is harder to achieve accuracy of dimensions and surface finish in oval type than in octagonal one and also more expensive to make. Reduce is not possible. Complies with ASME B16, 20, API 6A, JIS F 7102 510SR, JPI-7S-23.

-

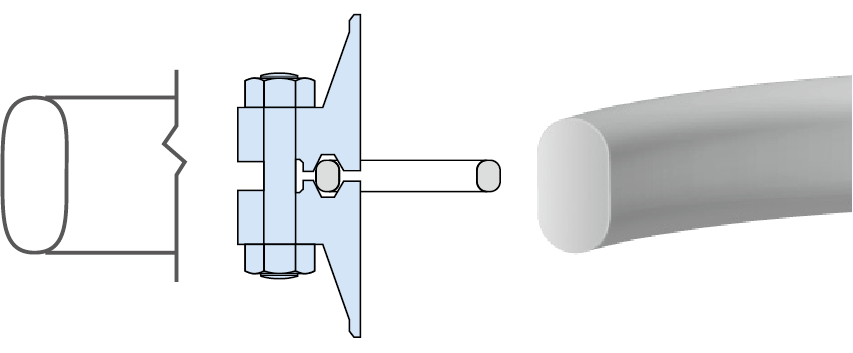

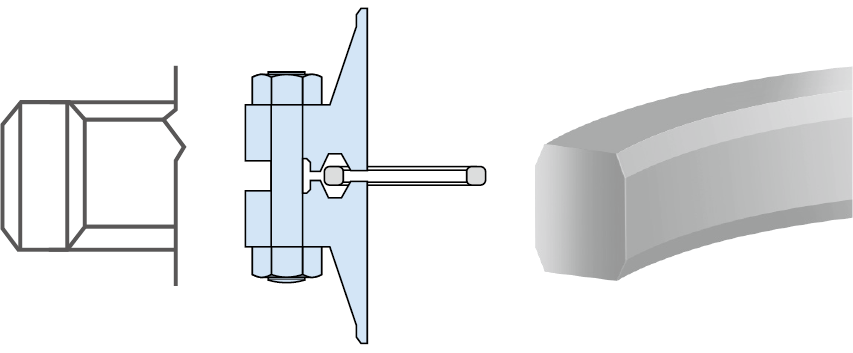

Ring joint Octagonal Type

More economical to make and more accurate in dimensions and surface finish than oval type because it consists of straight surfaces only. But more torque load is required to flow the gasket material into imperfections on the flange facings. Reuse is possible. Complies with the same standards as above.

-

Ring joint BX Type

Designed to API 6A for use with grooved flanges on special applications involving high pressures from 5,000 to 15,000 psi.

-

Ring joint RX Type

Designed to API 6A. Interchangeable with the oval and octagonal series of identical reference numbers, and used in the same flange grooves.